Government Support Services

K Corp Reliance Company (KRC) supports government-led fuel facility projects with licensed engineering, certified inspection, and compliance documentation services. We’ve partnered with the Defense Logistics Agency (DLA) and other contracting authorities on scopes involving Defense Fuel Support Points (DFSPs), fueling terminals, and associated infrastructure. Whether acting as a prime or subcontractor, KRC delivers project-ready support that aligns with government specifications, audit requirements, and construction milestones—both CONUS and OCONUS.

With extensive experience supporting DLA at DFSP facilities worldwide, KRC provides engineering, inspection, and project management services for both pre-award and post-award phases. Our work includes design reviews, facility condition assessments, construction oversight, commissioning, and turnover. Backed by deep technical expertise and a proven performance record, we help ensure that mission-critical fuel infrastructure meets the highest standards of safety, reliability, and compliance. Our global reach and ability to mobilize quickly make KRC a trusted partner in strengthening fuel system resiliency and advancing operational readiness.

Engineering & Technical Services for Federal Fuel Systems

Our scopes commonly include:

Proposal Development & Compliance: Assistance with technical documentation, cost analysis, and adherence to federal regulations to support successful bid submissions.

System Design Consultation: Expert guidance on automated operational technologies, industrial control systems, and fuel management solutions customized for government infrastructure.

Risk Assessment & Feasibility Studies: In-depth evaluations to identify potential challenges, assess risk, and optimize strategies for project execution.

Technical Demonstrations & Proof of Concept: Prototypes, simulations, and presentations to validate proposed solutions and demonstrate capabilities to federal stakeholders.

Site Visits & As-Built Documentation: Comprehensive site assessments and precise as-built drawings to ensure design accuracy and constructibility.

Engineering & System Integration: Turnkey solutions integrating automation, control, and industrial processes for bulk fuel facilities and critical infrastructure.

Inspection & Compliance Verification: Quality assurance inspections, NDE testing, and regulatory verification to ensure compliance with government standards.

Programming Development & Optimization: Design and optimization of software for SCADA, PLC, and other automated systems to enhance operational reliability and cybersecurity.

Maintenance & Technical Support: Ongoing lifecycle maintenance, diagnostics, and system upgrades to ensure long-term performance and reliability.

Turnover & Project Compliance: Final documentation, operational validation, and compliance certification to facilitate seamless project closeout and transition to operations.

API 653, 570, and STI SP001 inspections

Point Loma Support

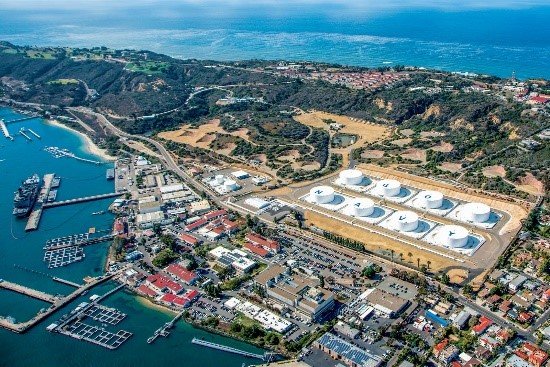

K Corp Reliance Company (KRC) was engaged by the Defense Logistics Agency (DLA) to support a strategic infrastructure initiative at Defense Fuel Support Point (DFSP) Point Loma in San Diego, California. As part of a critical Automated Fuel System Installation (AFSI) refresh, KRC delivered multidisciplinary engineering, documentation, and inspection services to enhance the operational integrity, compliance readiness, and automation capabilities of this high-security fuel terminal. Project Overview

DFSP Point Loma plays a vital role in supporting military operations across the Pacific theater. KRC’s mission was to modernize and validate fueling infrastructure by upgrading the legacy Automated Fuel Handling Equipment (AFHE) system, while integrating new control technologies without disrupting mission-critical operations. This required meticulous field coordination, SCADA integration, and collaboration with DLA engineers and other government stakeholders operating within restricted-access zones.

A central challenge was the seamless incorporation of the Fuel Oil Recovery Facility (FORFAC) – a complex network of valves, controls, and instrumentation—into the upgraded AFHE. KRC facilitated this effort through precise system assessments, technical consultation, and control systems expertise to ensure interoperability and automation continuity.

Key Capabilities Demonstrated

End-to-end support of federal fuel automation modernization

Subject matter expertise in SCADA, AFHE, and FORFAC integration

Successful delivery within controlled access and live operations environments

Proven execution in complex CONUS fuel terminal upgrades

Scope of Work

Technical Engineering & Integration Services

Conducted full-site mechanical inspections and condition assessments

Validated and updated redlined as-built piping and instrumentation diagrams (P&IDs)

Provided engineering recommendations to mitigate corrosion, improve system integrity, and align with DOD fueling standards

Integrated legacy components with new SCADA, PLCs, and control panel hardware

Design-Build & Project Support

Developed design-build RFP documentation and cost estimates (IGCE)

Facilitated design charrettes and conceptual planning

Supported bid evaluations and contractor selection processes

Delivered construction-phase technical assistance and compliance oversight

Program Coordination & Compliance

Collaborated extensively with DLA project leads, base engineers, and interagency stakeholders

Delivered SPCC-compliant documentation and system validation packages

Ensured operational security and environmental compliance throughout fieldwork

Outcome

KRC’s contribution to DFSP Point Loma ensured a smooth and secure transition to upgraded fuel-handling infrastructure while maintaining full operational readiness. Our technical solutions, compliance support, and integrated design services helped DLA strengthen the site’s resilience and prepare for future audits, modernization, and mission demands.

DFSP Manchester

DLA Contract Support

K Corp Reliance Company (KRC) delivered specialized engineering, inspection, and compliance documentation services to the Defense Logistics Agency (DLA) in support of ongoing operations at Defense Fuel Support Point (DFSP) Manchester. As part of our federal fuel system portfolio, this project showcased KRC’s ability to support mission-critical infrastructure under high-security conditions, integrating field expertise with real-time documentation and regulatory alignment. Project Overview

KRC was tasked with enhancing the operational integrity and compliance posture of DFSP Manchester through hands-on field engineering and technical program support. Our work included as-built verification, mechanical inspections, and SPCC-aligned documentation—all crucial components in maintaining audit-ready status and extending lifecycle readiness of critical petroleum infrastructure. We partnered closely with DLA engineers and contractors to streamline project planning, accelerate system assessments, and ensure infrastructure continuity across both legacy and upgraded components.

Key Capabilities Demonstrated

Turnkey compliance support under strict federal security protocols

Integrated mechanical, civil, and control systems insights

Mission-driven fuel infrastructure support aligned with DOD objectives

Proven ability to deliver results across both CONUS and OCONUS locations

Scope of Work

Engineering Support & Documentation

Field verification and redline updates to legacy drawings

Development of complete technical documentation packages

Support for SPCC, regulatory compliance, and asset visibility

Inspection & System Assessment

Mechanical system inspections, including valves, piping and containment structures

Visual condition assessments and field reports to inform maintenance strategy

Coordination of findings with system engineers and project stakeholders

Ongoing Contract Services

Real-time collaboration with DLA personnel, design-build contractors, and technical consultants Engineering review of proposed modifications and system upgrades

Site readiness support for environmental audits and federal oversight

Outcome

Through disciplined execution and responsive field coordination, KRC helped DLA maintain critical infrastructure documentation and compliance posture at DFSP Manchester. Our proactive engineering support contributed to long-term operational readiness, enabling uninterrupted fueling operations and positioning the site for future modernization efforts.

USCG Support – API 570 Inspections

K Corp Reliance Company (KRC) provided certified piping inspection services for U.S. Coast Guard fueling infrastructure across multiple locations. These inspections were performed under API 570 standards and supported system safety, regulatory compliance, and long-term infrastructure planning for active fueling operations.

Project Overview

KRC’s inspection team supported Coast Guard facilities requiring compliance inspections for fuel piping systems. Work was conducted at multiple coastal and interior locations and included mechanical assessments, documentation updates, and reporting to meet internal and federal review standards.

Challenges & Considerations

Each site presented unique access and environmental challenges, from remote weather-exposed terminals to facilities operating under active fueling demands. Inspections had to be completed on compressed timelines with minimal operational disruption. KRC’s inspectors were equipped for rapid deployment and conducted evaluations in compliance with USCG protocols.

Scope of Work

Performed API 570 piping inspections across active fueling systems

Verified mechanical integrity, weld conditions, and support structures

Conducted visual inspections and wall thickness measurements

Identified corrosion, mechanical stress, and regulatory deficiencies

Prepared full documentation packages for USCG review

Supported planning for system upgrades and repairs based on findings

Outcome

KRC delivered detailed inspection reports aligned with API 570 standards, supporting the Coast Guard’s ability to prioritize repairs, plan infrastructure improvements, and maintain fuel system compliance. Our work helped ensure ongoing safety and reliability across key fueling sites.

Start a Project with KRC

Whether you need a scope of work reviewed, a certified inspection scheduled, or a long-term partner for ongoing compliance — KRC is ready to support your project from day one.

Please fill out the form or Call: (907) 921-8647